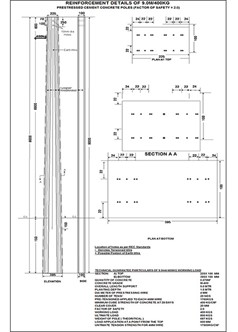

PSC Poles 9 Meter

Physical specification

Along the minor axis, two holes shall be provided.

The pole will have its 1st hole at 100mm from the top, followed by the 2nd hole at 200 mm from the top.

The pole shall be rectangular in cross-section. The top section shall be 225mm X 100mm, and the bottom section shall be 395mm X 100mm, with a total length of 9 meters and an overall weight of 670 kgs. Each pole shall have 18mm diameter through holes suitable for a 16mm disc bolt at the following distance from the top along the minor axis. Each bar shall have pre-stressing steel wire of 4mm diameter with a guaranteed ultimate strength of 175 kgs/mm2, 20 nos. as tensioned wire.

Each pole shall be embossed or engraved with

Month and year of manufacture

Maker name, serial number, and making symbol

Transverse strength of pole in kg

Each pole shall have an earthing of 08 SWG wire embedded in concrete during manufacturing so that the end of the wire is left projecting from the bar to a length of 50mm at 250mm from the top and 150mm below ground level. i.e., 1350 mm from the bottom end. The earthing wire provided shall not be allowed to come in contact with pre-stressing wires. Further, each pole shall be equipped with M.S stirrups as per ISS 432/1966 with anneals wire of ultimate strength of 32 kg/mm square and 4mm M.S wire ten in numbers spread throughout the length at suitable spacing. Permissible tolerance in plighting shall fully confirm the relevant provision of ISS: 1342/1980 and ISS: 1678/1978 and the latest publications.

Technical Specification

PSC poles shall comply with the recommendation of REC as per the specification 15/1979 (with the latest amendment) where there are conflicts regarding specific requirements. The ISS specifications complied with are:

ISS:1678/1978

ISS:2985/1966

ISS:7321/1974

The concrete mixture shall designed to the requirement laid down to controlled concrete in ISS: 1343/1980 and ISS: 456/1973. The cubes’ strengths at 20 days shall not exceed 420 kg/mm2. The maximum compressive stress in concrete at the time of transfer of pre-stressed shall not exceed 0.8 times. The ultimate moment capacity in the longitudinal direction should be one-fourth of that in the transverse direction. The cube and concrete strength at transfer shall be at least half the 28 days strength, i.e., 420 X 0.5 = 210 kgs/mm2. The concrete shall be mechanically compacted by shuttering vibrators.

The poles shall have a safety factor of 1.0 against the first crack load and not less than 2.0 against failure for loads applied at 0.06 meters from the top with 1.6 meters of pole inside the ground. The guaranteed minimum ultimate transverse load shall not be less than 800 kgs.

transfer of pre stressed shall not exceed 0.8 times.